Uniting glass forming and inspection

The glass plant of the future will have production processes that will amaze the glassmakers of the past. Integrated equipment will document, analyze, and react to data automatically to ensure product quality and optimize operation. Products will be immediately traceable. Employees will be safer and more productive. And plant operations will run at peak efficiency to achieve optimum productivity and result in increased profitability.

End to End Technology

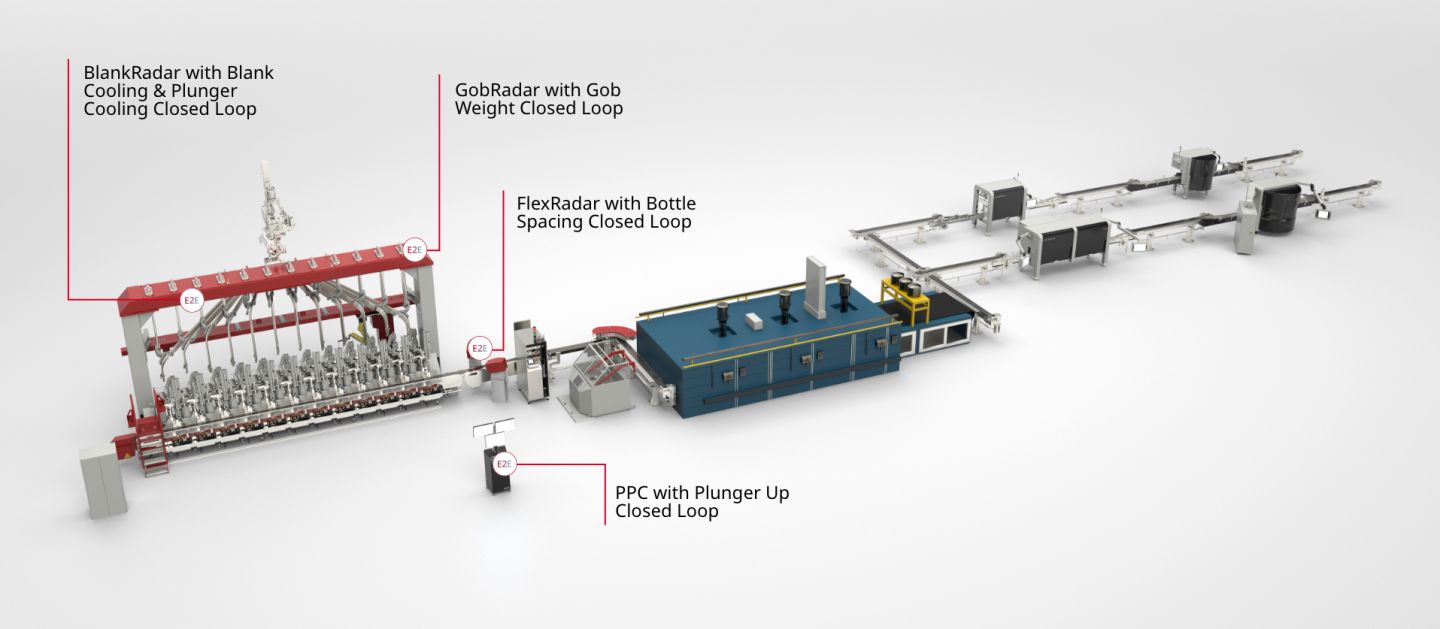

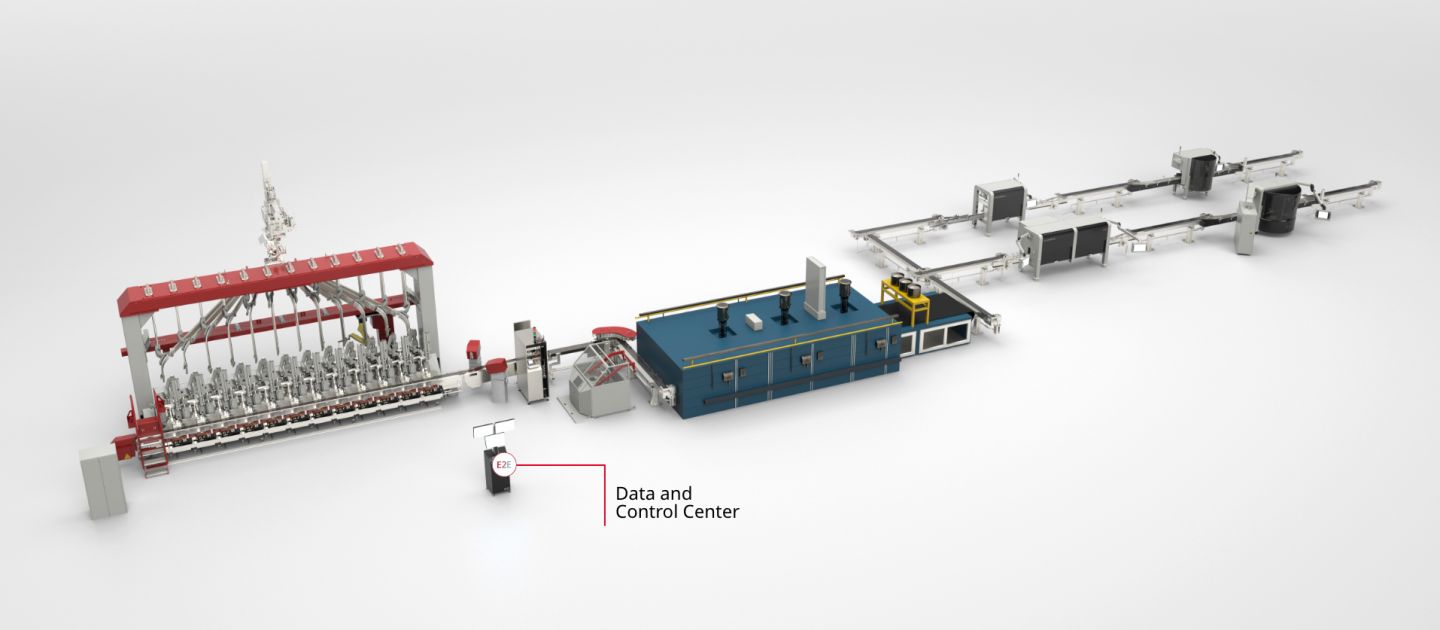

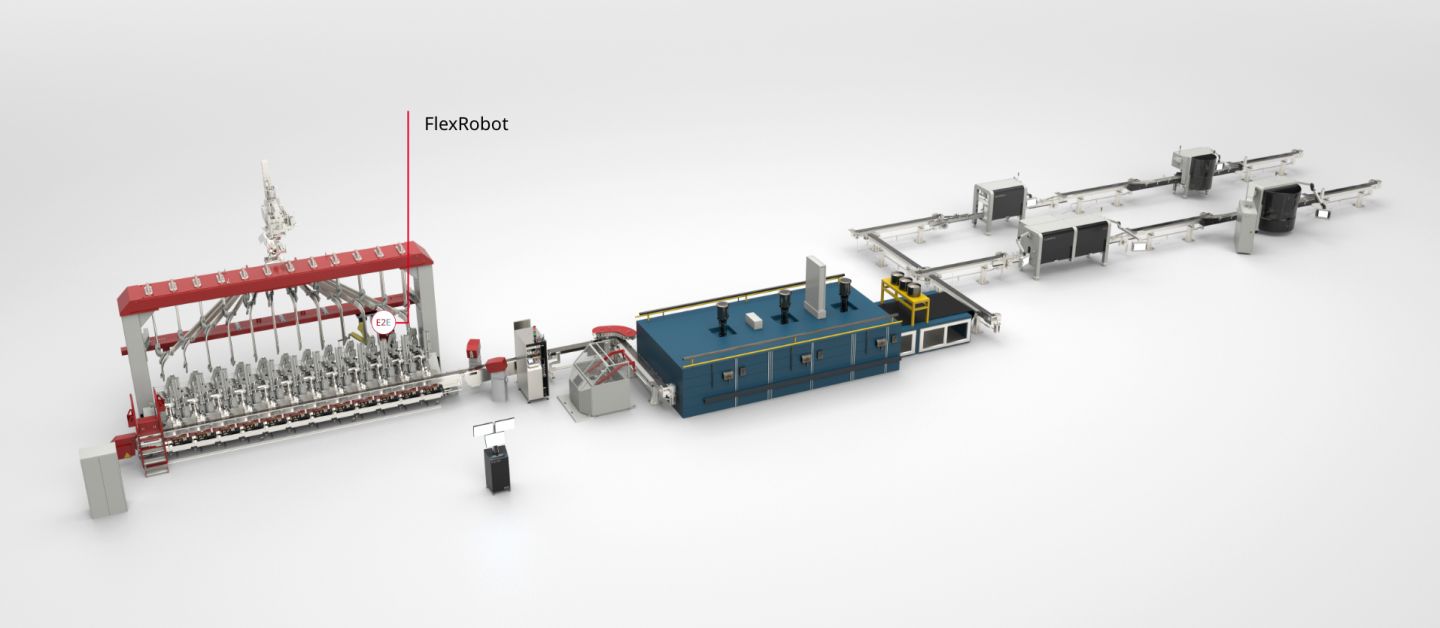

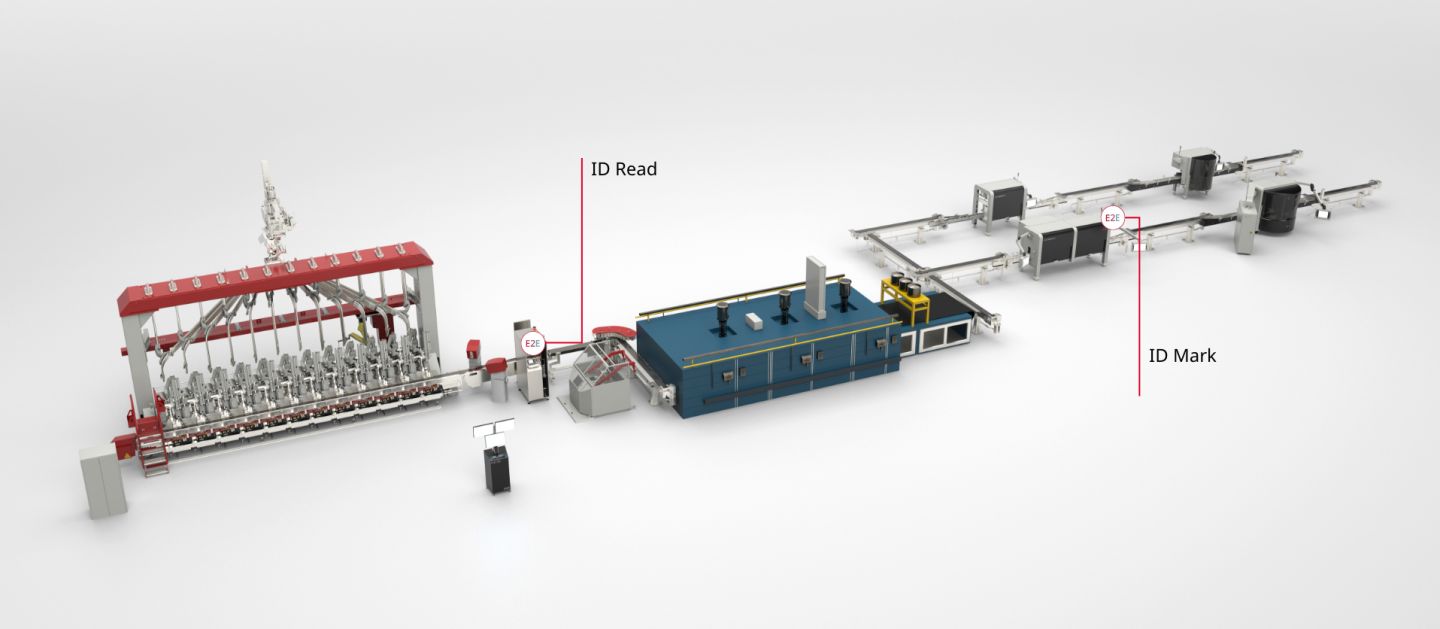

End to End brings together BEG's unique technologies for hot end forming and cold end inspection by collecting data and automatically communicating adjustments between the processes. This technology monitors forming data parameters which are matched with inspection results, enabling self-learning to optimize forming process settings and achieve the highest plant performance.

Technology Elements

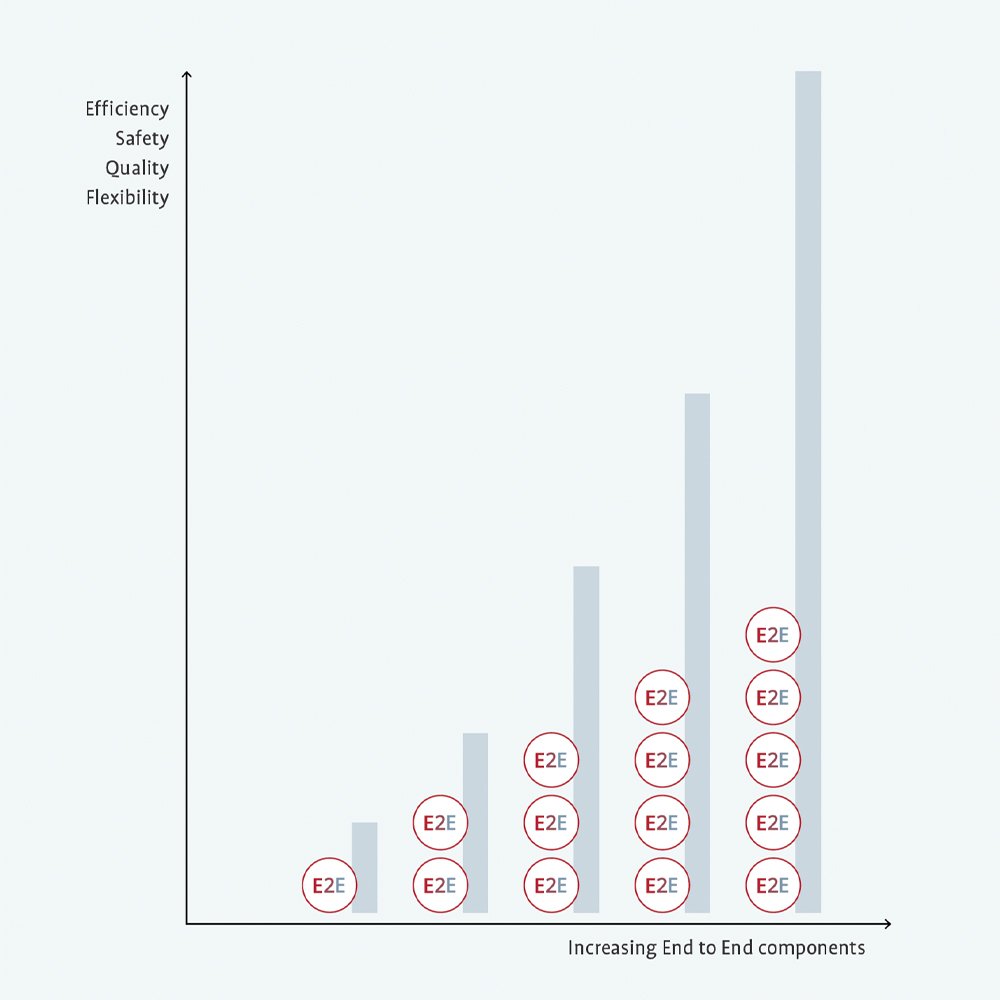

End to End technology elements can be installed without having to commit to a complete End to End line. Current elements can be:

Combining individual End to End technology elements provides much greater results. Synergies are achieved so that they become Stronger Together.

One plant, one partner

For the best return on investment, it makes sense to work closely with a single supplier who has an unrivalled knowledge of forming and inspection. The Emhart point of difference is that we are the only company to offer world-class machinery for both processes.

By integrating these technologies, we can provide more sensors at the machine, more automation, more closed loops and more data. Emhart customers can look forward to better ways of working, with improved safety, traceability and reliability, in an environment where a 1% increase in efficiency can result in tremendous earnings. Ultimately helping glass plants to run as profitably as possible.