With Stability into the Future

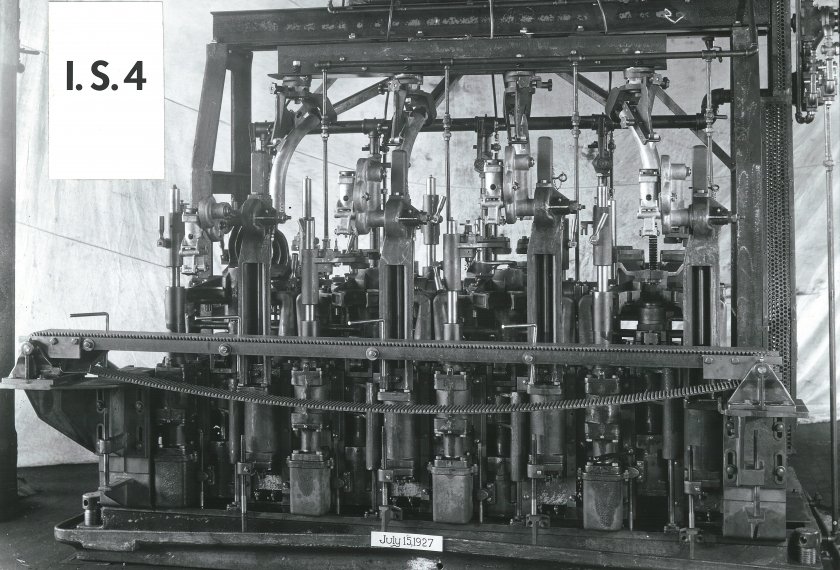

We have a century of growth and innovation behind us. Our founders created the first glass gob shearing devices and plunger feeders, laying the foundations for the automation of the glass container industry. Throughout our development, we have sought out opportunities to bring new members into our group. In 1982, we acquired Powers Manufacturing Inc., the US-based specialist in high quality cold end inspection equipment. The Powers facility was ideally suited for producing our Total Inspection Machines TIM. In 2007, we brought a new depth to our cold end expertise with the acquisition of ICS Inex Inspection Systems. Established in 1855 as the Barry-Wehmiller Machine Co. supplying early production line innovations, the company created Optitron, the first inspection machine for refillable bottles, in 1955. The following decades saw Inex establish a strong position in glass container inspection devices for the pharmaceutical, food and general packaging industries. Today, we offer a comprehensive range of inspection systems, high precision on-line sampling systems and label inspection devices.

Since 1998, being part of the Bucher Industries Group has brought us even greater financial and organizational strength. Based in Switzerland, Bucher is a diverse industrial group with interests in related areas of mechanical and vehicle engineering including agriculture, street sweeping, beverage production and hydraulics. In 2011, we struck a landmark joint venture with Shandong Sanjin Glass Machinery Co., China’s undisputed market leader for container glass machinery and equipment. This collaboration offers a perfect fit in terms of product portfolio and represents the ideal way for both companies to meet local demand for efficient, accurate glass production.

Today, Bucher Emhart Glass is established as the world‘s leading international supplier of glass container manufacturing solutions, including equipment, controls, parts, and support. We continue to work towards innovations that will deliver genuine gains in productivity and efficiency for our clients.

As well as supporting our customers, we support our own people. To help our employees develop in a positive way, we aim to generate a positive working environment where people feel part of a team. Strong internal knowledge support groups help staff members leverage expertise across international and departmental boundaries. Suppliers, too, are treated as partners in adding value: we trust them to deliver on time and we pay on time when they do. Our strong reputation and low staff turnover are testament to the value of our culture.