Adjusting plunger up motion

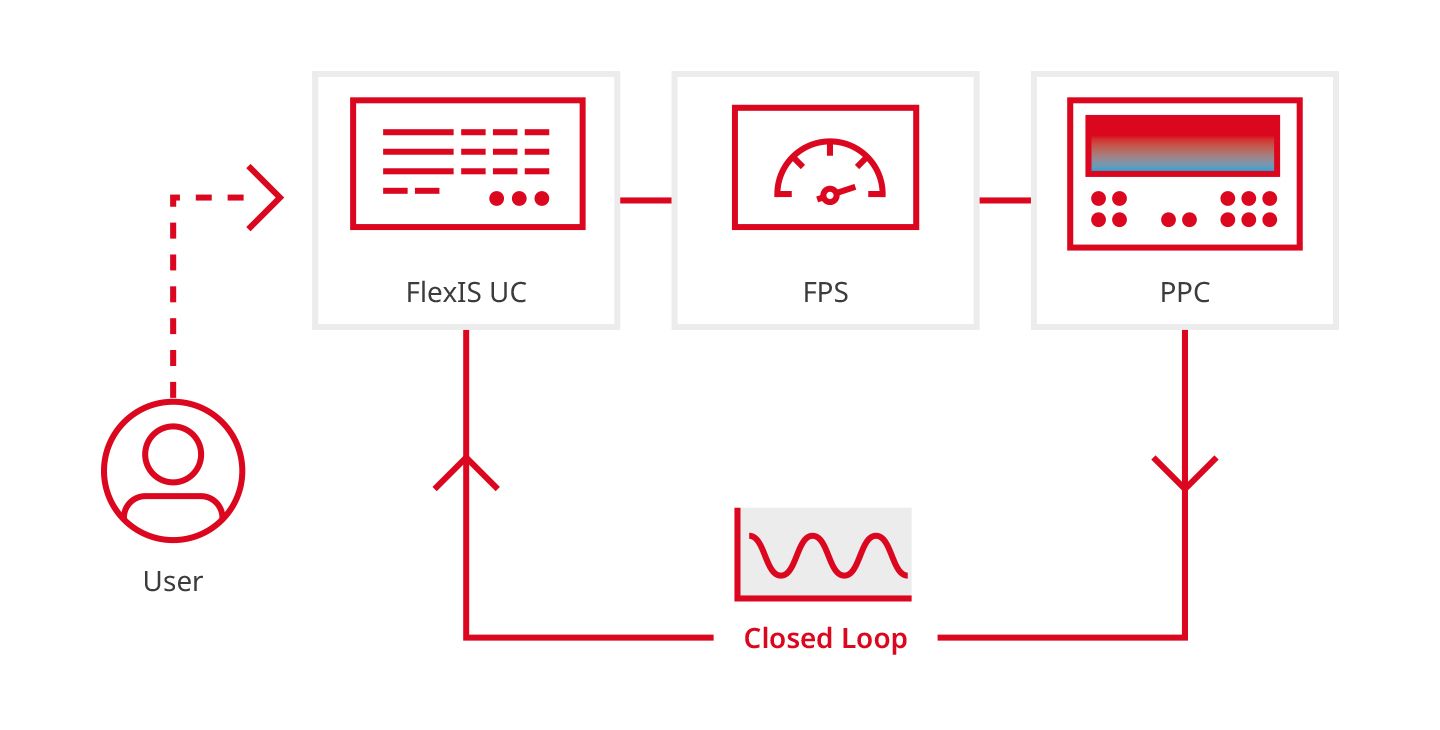

FlexIS Plunger Up Control PUC adjusts the plunger up motion in Press & Blow productions. The system takes care for having the cavity filled entirely with glass at the desired time.

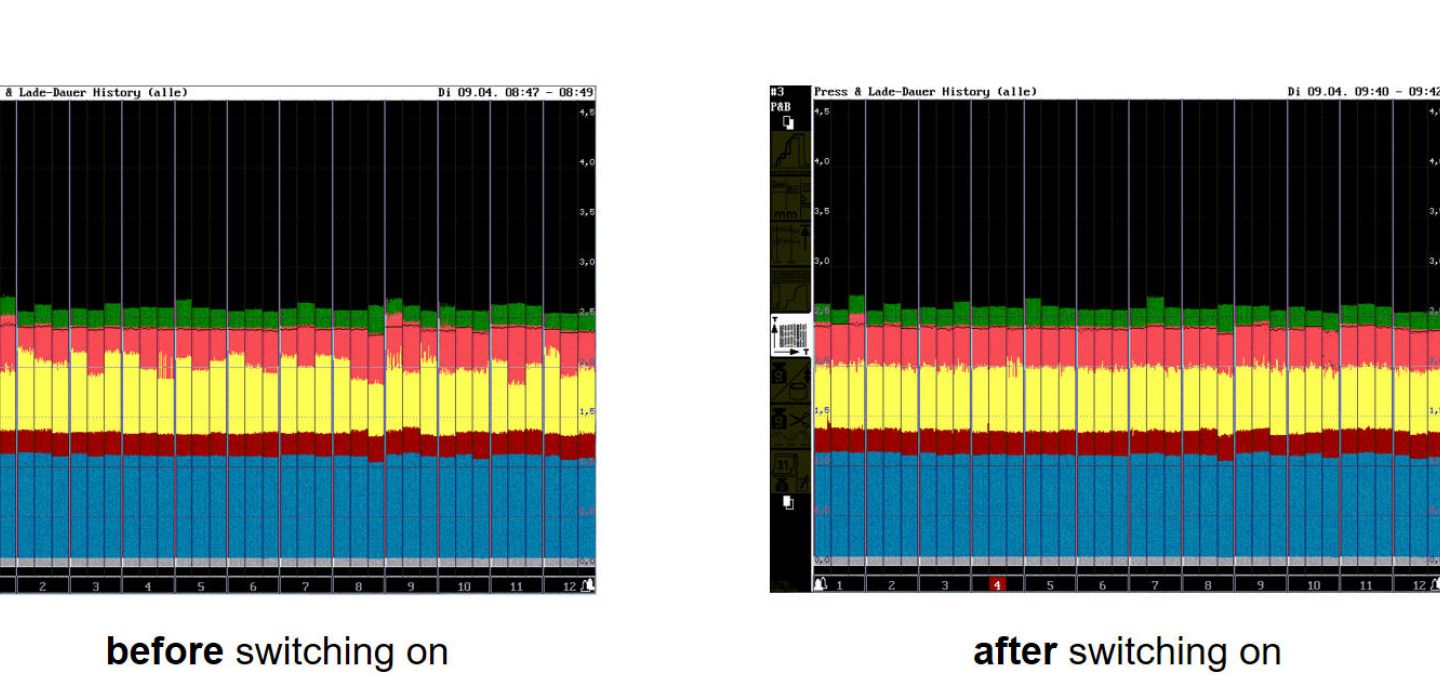

The result of this continuous adjustment is a well maintained full contact time throughout the production run and across all cavities of the machine (see picture below – situation before and after switching on). Customers report that also the start up after a job change is greatly supported by the system – plunger up adjustment is automatically done within a few cycles.

Features

- FlexIS Plunger Up Control PUC is fully integrated into the FlexIS controls, stored in the job file

- Uses FPS multi pressure pressing

- Automatically adjusts FPS pressure levels and switch points between pressures according to press curve

- PPC remote access through the FlexIS remote access system

Benefits

- Reduced complexity / better ease of use

- Improved start up after job change

- More regular plunger motion due to higher initial pressure levels

- Keeps process steady / less variation, over time, from cavity to cavity, less stops, higher quality / pack rate

- Optimal addition to FlexIS remote service. Experts can support remotely auditing real time PPC and Plunger Up closed loop.

Downloads

TNB248 - FlexIS Basic Closed Loop Equipment

PDF | 21.10.2020

TNB126 - FPS for Plunger Up – Performance Enhancement

PDF | 26.10.2020

TNB156 - Plunger Up FPS with Exhaust Valve

PDF | 26.10.2020

TNB310 - Plunger process control 2

PDF | 25.04.2023